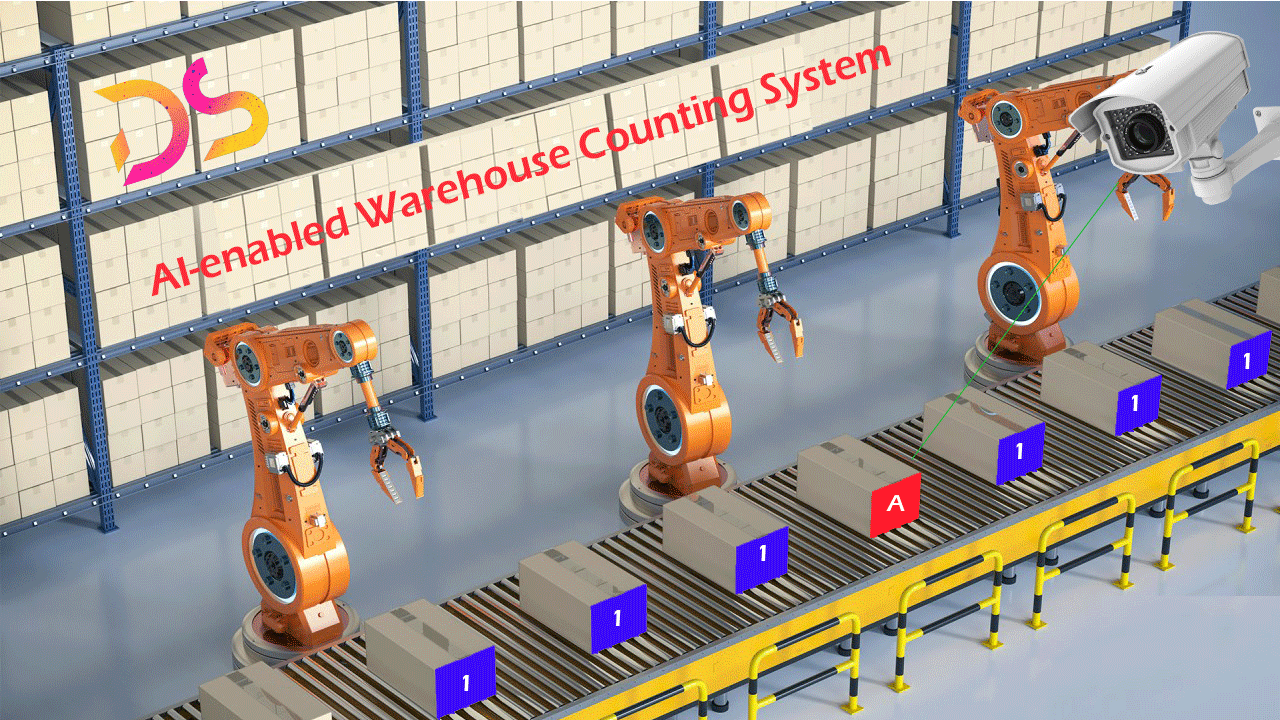

How AI-Enabled Warehouse Counting Systems Are Transforming the Warehouse Industry?

AI-Enabled Warehouse Counting Systems

AI-enabled warehouse technology is pushing the limitations of what is possible for B2B operations. As a result, the standards for fulfilling the demands have become tougher than ever. AI technology is a game changer for the warehouses seeking to meet client’s requirements and optimize efficiency. Warehouse management and AI applications are playing a pivotal role in transforming warehouses. AI is shaping the future of inventory management and revolutionizing the way we handle inventory.

Current warehouse counting system

Businesses running logistics and supply chain operations need to perform the counting of their inventory regularly. In today’s times, the manual counting of the warehouse inventory is such a slow and unreliable task which further delays operations as well as increases the expenses. Some of the challenges that businesses may face due to the manual counting process include error-prone and malpractice, simple sensor-based solutions, object detection and classification in warehouses, integration of sensor data into the monitoring system, and more.

Challenges in warehouse management

A competent smart warehousing and AI integration system helps tackle several challenges including:

• Inventory management to avoid understocking or overstocking of products

• Quality control process to minimize any kind of product damages

• Efficient order management to tackle slow order processing and inaccurate orders

• Integration of sensor data to current monitoring system

• Count of packages due to missing artifacts

Therefore, businesses require an automated counting process to address such challenges. AI-enabled warehouse counting system by Digicane Systems is a game changer that ensures accurate counting of packages, out-of-the-box QR code reading, proof of counts and malpractices, etc. This system extends to a wide range of industries from retail to e-commerce, manufacturing to logistics, and more. This way, the system streamlines warehouse management, and ensures that all packages are accurately counted and accounted for.

The bright side of AI-enabled warehouse counting systems

Employing AI-enabled systems comes with amazing advantages including:

• Accuracy

• Real-time data analysis

• Error reduction

• Enhanced decision making

• Automation

• Enhanced customer satisfaction

Digicane Systems has developed an automated solution for counting using deep neural networks and custom computer vision technology in warehouse management. Powered by advanced AI algorithms, these systems have become the vigilant guardians against errors and minimize discrepancies that may arise due to manual tracking. Your warehouse will become more efficient, and you will be able to improve your profits due to less wasted efforts that may arise due to errors in the labeling and counting of consignments.

AI-driven inventory management and control systems can help with a more accurate and speedy quality control process. This can ensure that only the defect-free products return to the inventory. Overall AI in warehouse management can automate the day-to-day tasks and reduce manual errors while maintaining high-quality operations.

AI-based goods recognition and counting

Scanner-free logistics operations based on AI increase accuracy as well as save a considerable amount of time. What AI-enabled warehouse counting systems can perform involve:

• Measuring and counting products, finding and decoding barcodes, and QR codes

• Increased quality control through video documentation

• Recognition of products for optimal packing

• Goods recognition and consistency checks

• Integration with any third-party system on demand

• Smart package type detection to identify packages

The computer vision technology in warehouse management systems has machine learning functions, and it uses image recognition software to recognize products. These systems track the movement of products by taking pictures and noticing the changes. This further enables businesses to regulate inventory levels. This ensures that each product lands at its appropriate place, and that there is no mistake in the storage and delivery of products from the warehouse.

By applying AI and automation in warehouse inventory management, firms can keep them free to pursue critical business tasks that spur business growth instead of wasting their precious time on manual monitoring. Before diving into the world of AI-enabled warehouse counting systems, you need to choose the right partner for operational excellence. Here Digicane Systems can help you out to give your business an operational advantage as we all know that the future is automated and AI-powered.

Future trends for AI in warehouse counting

AI-driven technology in warehouse management will continue to evolve further in the coming years, enabling more accuracy. This will further help businesses take an anticipative approach to manage potential issues before they could happen. Drones, AI cameras, and robots will be integrated to assist with material counting, conducting real-time warehouse monitoring and control processes, inventory checks, and identifying inventory-related issues.

AI-assisted warehouse operations and management will play a crucial role in predicting stock and managing processes. AI is not an abstract concept, but it is a tool that will reshape warehouse inventory operations. It’s all about real-world benefits like reduced errors, faster order fulfillment, and more. So, revolutionize your warehouse operations with Digicane Systems – a pioneer in AI-driven inventory management and control. From smarter inventory counting and related processes to streamlining processes, they will transform the way you perform warehousing operations.